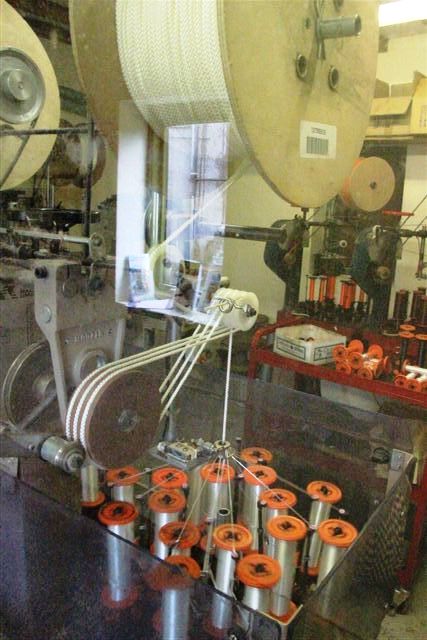

On Wednesday, 21 May 2014, we visited Outhwaite Ropemakers, Hawes.

We had a guided tour of Outhwaite Ropes by the owner, Peter Annison. Peter is the person who understands, specifies and maintains the machinery at this unique site.

Natural fibres, derived from the sinewy parts of plant stalks and leaves, have been used to make rope since ancient times. Flax, sisal and jute are still used in Hawes. Hemp was formerly used a great deal but is now virtually unobtainable. Following the preparation of yarn, rope is twisted in the traditional way. A necessary additional step with some ropes was to give them a smoother, less hairy appearance by treating them with size (starch) to stick down the surface fibres.

The introduction of man-made fibres has given the Hawes ropemakers a greater choice of raw materials. Their properties of durability, water-resistance and strength are useful for agricultural ropes which get hard outdoor use and for many modern specialist cords and braids.